1000/1000

Hot

Most Recent

Hemp, or Cannabis sativa L., is an oleaginous plant known as one of the oldest plants cultivated by humankind, specifically for medicinal properties and non-edible fiber content.

Hemp, or Cannabis sativa L., is an oleaginous plant known as one of the oldest plants cultivated by humankind, specifically for medicinal properties and non-edible fiber content [1]. The letter “L” stands for Linnaeus in recognition of the contributions of the father of modern taxonomy, Carolus Linnaeus, who first named the species as Cannabis sativa [2]. This plant is widely known to be the major source of cannabinoids, including cannabidiol (CBD), tetrahydrocannabinol (THC), cannabichromene (CBC), cannabigerol (CBG), and cannabinol (CBN). Cannabinoids have shown strong remedial potential against inflammation, depression [3], nausea, epilepsy, and other effects of clinical relevance [4][5]. Initial uses of cannabis date back to almost 5000 years in China [6]. Since then, hemp consumption has been spurred on by its wide range of properties and uses from one civilization to another through consecutive millennia. The first academic research on the extraction of bioactive ingredients of hemp, to the best of these authors’ knowledge, was conducted by Yamauchi et al. in 1968 [7].

From the taxonomical point of view, hemp belongs to the family of Cannabinaceae [8] that includes three subspecies, namely Sativa, Indica, and Ruderalis. The differences between these three subspecies mainly lie in the overall shape of the plant, the applications, and the most suitable climate for its growth. The division of the cannabis strains into hemp and marijuana is simply a wrong nomenclature that is wholly misconceived with a broader classification of cannabis [9]. The two names differentiate varieties with Δ9-tetrahydrocannabinol (Δ9-THC) contents of less than 0.3 wt.% (hemp) from those having more than 0.3 wt.% (marijuana) that induces psychoactive effects [10]. Occasionally, these terms are falsely adapted and interchangeably applied in the literature [11][12]. The cannabis with a THC content of over 0.3 wt.% (marijuana) is outside of the scope of this review paper.

Hemp has historically been attractive for its top-quality fiber and edible oil; however, with the advancement of synthetic fibers, as well as mounting public anti-drug movements, it was categorized as a controlled substance by the 1968s prohibition legislation. This prohibition, under drug enforcement laws [13], banned the production and research on hemp products, putting the United States far behind more than 30 other nations that considered the plant to be an agricultural commodity [14]. In the early 1990s, commercial hemp cultivation and its research and development were promoted in the U.S. Ever since, a growing number of states have enacted the legislation and have expanded state-level research and production. The status of legality, decriminalization, permission for medical use, and the specific state laws can be found in continuously updating marijuana maps [15].

The outstanding therapeutic effects along with the economic benefits to local communities resulted in increasing public support and the eventual legalization of these products in many countries around the world and recently in several states in the U.S. Beginning with the 2014 Farm Bill, the growth and production of hemp experienced a partial relief in the U.S. [13], and the first medically-oriented legal product came to the market in June 2018, creating a huge market for CBD [16][17]. Nevertheless, due to the psychoactive properties of the THC, the upper limit of 0.3 wt.% (dry biomass weight) still remains a key barrier between the cannabis flower and the drug [13][18] in most U.S. states and the European Union [19]. Based on the 2017 congressional research, the total hemp market was about 700 million USD in the U.S. [13], while in light of the recent openings, this number will hit 20 billion USD by 2024, pushing the global spending to go beyond 40 billion USD worldwide, according to Arcview market research [20].

Yet, developing various feasible technologies that are both legitimate and economic are important steps that need to be taken before industrial-scale production standards can be set. Dealing with a living plant that is controversial and inhomogeneous in growth due to different soil fertility levels [21], as well as other local factors, poses challenges on the determination of optimum harvesting conditions to obtain a maximum cannabinoid content. On the other hand, establishing effective and energetically efficient large-scale extraction protocols are keys for the successful resolution of the challenges. Despite the routine lab-scale extraction methods, the variables affecting the choice of extraction method, as well as the final extraction yields, are not well understood. Further, the growth and processing of this plant are going through a transition phase that requires closing the knowledge gap in the extraction field to set a complete processing system up.

Throughout the hemp industry, the term “extraction” is used in two different contexts and categories: (1) the trichome category, in which the extraction of cannabinoids and terpenes from trichomes takes place with the aim of producing medical or recreational grade supplements; and (2) the seed category, in which the extraction of fatty acids or lipids from hemp seeds takes place. Triglycerides make up to over 30% of hempseed weight [22][23], which is the suitable form of lipid for trans-esterification into fatty-acid methyl esters (FAME) or biodiesel [24]. In addition to biodiesel production, the extracted lipid has a wide spectrum of applications in the cosmetics [25] and food industries [26]. The extraction of lipids from seed (seed category) is outside of the scope of this review. We will focus mainly on the trichome category, discussing the processes involved in cannabinoid and terpene extraction.

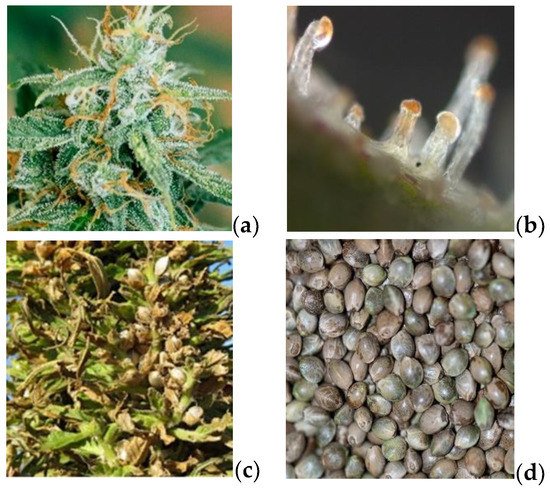

Assuming that a typical farm produces male and female plants in equal numbers, the females appear shorter with many flowers, while the males are taller and exude pollens only (Figure 1). If harvested and dried on time, the female flowers contain a significant amount of cannabinoid, whereas the pollens from males pollinate the flower buds to produce seeds [27]. That is why the growers of cannabinoids usually root the male plants out prior the pollination.

Figure 1. Hemp flower. Cannabinoid-rich female flower buds before pollination (a) and a microscopic image of the trichomes in the buds (b). The adult seeded flower is the result of pollination (c), and the hempseeds are produced by pollinated buds (d).

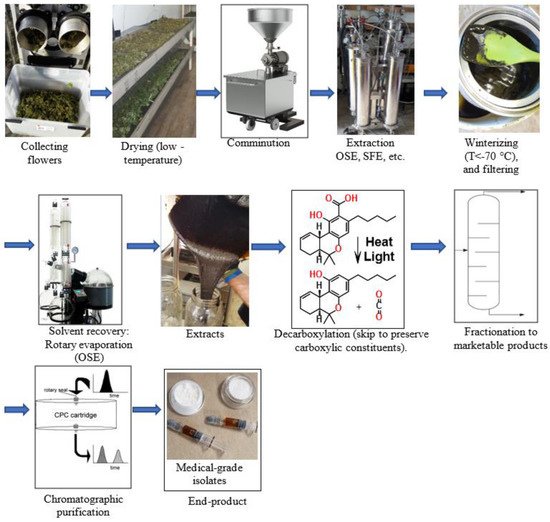

Figure 2 shows the processing steps required to produce cannabinoids and terpenes from the hemp flowers. Depending on the final analytes of interest or the chosen extraction method, some of these steps might be modified. Once harvested, the hemp flowers should be trimmed manually or with the help of bucking machines. The flowers then need to be dried (in the absence of sunlight to prevent the photochemical transformation) and milled to reduce particle size. The shredded biomass is transferred to extraction tanks and immersed in the solvent(s) of choice for a known period of time to let the extraction take place.

Figure 2. Process flow diagram showing the downstream processing steps needed to produce cannabinoids from Cannabis sativa L. OSE: organic solvent extraction; SFE: supercritical fluid extraction.

While being exposed to the solvent, in addition to the extraction of cannabinoid and terpene, usually volatiles, moisture, and heavy residues also leave the plant matrix as co-extracts. The latter includes pigments, phospholipids, fatty acids, heavy metals, etc., and resembles a highly viscous, gooey black gum that forms an inhomogeneous tar when exposed to increased temperatures. This black mixture is called wax and needs to be removed before further processing, as it spoils the thermodynamics of separation. Winterization involves the separation/sedimentation of the waxy fractions by the deep freezing of the crude for over 24 h [28][29] and subsequent filtration of the solution. The separated wax is used in electronics, candles, machinery lubricants, as well as other applications. Once winterized, the solvent is removed using a rotary evaporator and recycled back to the extraction process. The obtained material can then be distilled to fractions that can be marketed as vapes, edibles, topicals, food supplements, or additives.

Medical or therapeutic applications require the products to be ultra-pure (beyond 99% purity), which can be attained via chromatographic methods, crystallization, or distillation techniques [29][30]. One major downside of distillation is the involvement of thermal energy. Neutral cannabinoids (THC, etc.) do not occur at significant concentrations in the plants [31][32][33] and are usually produced by thermal transformations during extraction. Therefore, some extra caution should be exercised during the process to maintain the THC contents controlled, especially in the production of medical products.